EVO MES (Manufacturing Execution System) system is an important management tool in the manufacturing industry. Designed to optimize production processes and manage the entire system, EVO MES brings many important benefits to businesses. In this article, we will introduce the EVO MES system and focus on the benefits it brings.

EVO MES is part of the EVO SMART FACTORY, a Made in Vietnam smart factory solution suite. This solution not only helps customers digitally transform management of entire production activities but also optimize SQCD (Speed, Quality, Cost, Progress).

EVO MES complies with international standards ANSI/ISA-95 and ISO 22400-2, ensuring security according to ISO 27001 standards. With a flexible design, EVO MES has the ability to easily customize according to requirements and requirements. adapt to the actual process of each business. This helps optimize the production process and ensure scalability and future growth of the business.

1. Features of EVO MES

Optimize Production Management

One of the most important benefits of the EVO MES system is the ability to optimize production management. This system helps track the entire production process from start to finish, from importing raw materials to the final product. Through data collection and processing, EVO MES provides detailed information about production performance, helping management predict and react faster to problems and fluctuations in the production process.

Effective Quality Management

The EVO MES system also plays an important role in product quality management. It allows recording and tracking quality data during the production process. This helps detect quality issues early and intervene promptly to ensure the final product meets quality standards.

Optimize Labor Management and Production Process

The EVO MES system provides an overview of production and labor activities. It helps management track the performance of workers, production processes and machine resources. This helps improve labor efficiency, reduce downtime and optimize production processes.

Manage Technical Records and Papers Effectively

MES systems make the management of technical records and paperwork more efficient. Important technical data such as manufacturing instructions, technical documents and licenses can be stored and accessed easily. This helps ensure that all information relating to products and manufacturing processes is always up to date and ready for use.

Connect IIOT, PLC, SCADA Devices

MES systems are a bridge between the traditional manufacturing world and new technologies such as IoT (Internet of Things), PLC (Programmable Logic Controller) and SCADA (Supervisory Control and Data Acquisition). It allows businesses to connect and interact with these devices to collect data and control production processes. This helps create smart manufacturing environments and respond quickly to changes in the industry.

Real-Time Statistical Report

Finally, the EVO MES system provides the ability to generate real-time statistical reports. Thanks to continuously updated data, management can review production performance, product quality and process status anytime, anywhere. This helps them make decisions based on real-time information and improve management processes.

In conclusion, the EVO MES system is not only a production management tool, but also an important part of the digital transformation in the manufacturing industry. With the ability to optimize production processes, quality management, labor, and many other benefits, it plays an important role in improving business performance and competitiveness.

2. Benefits of EVO MES

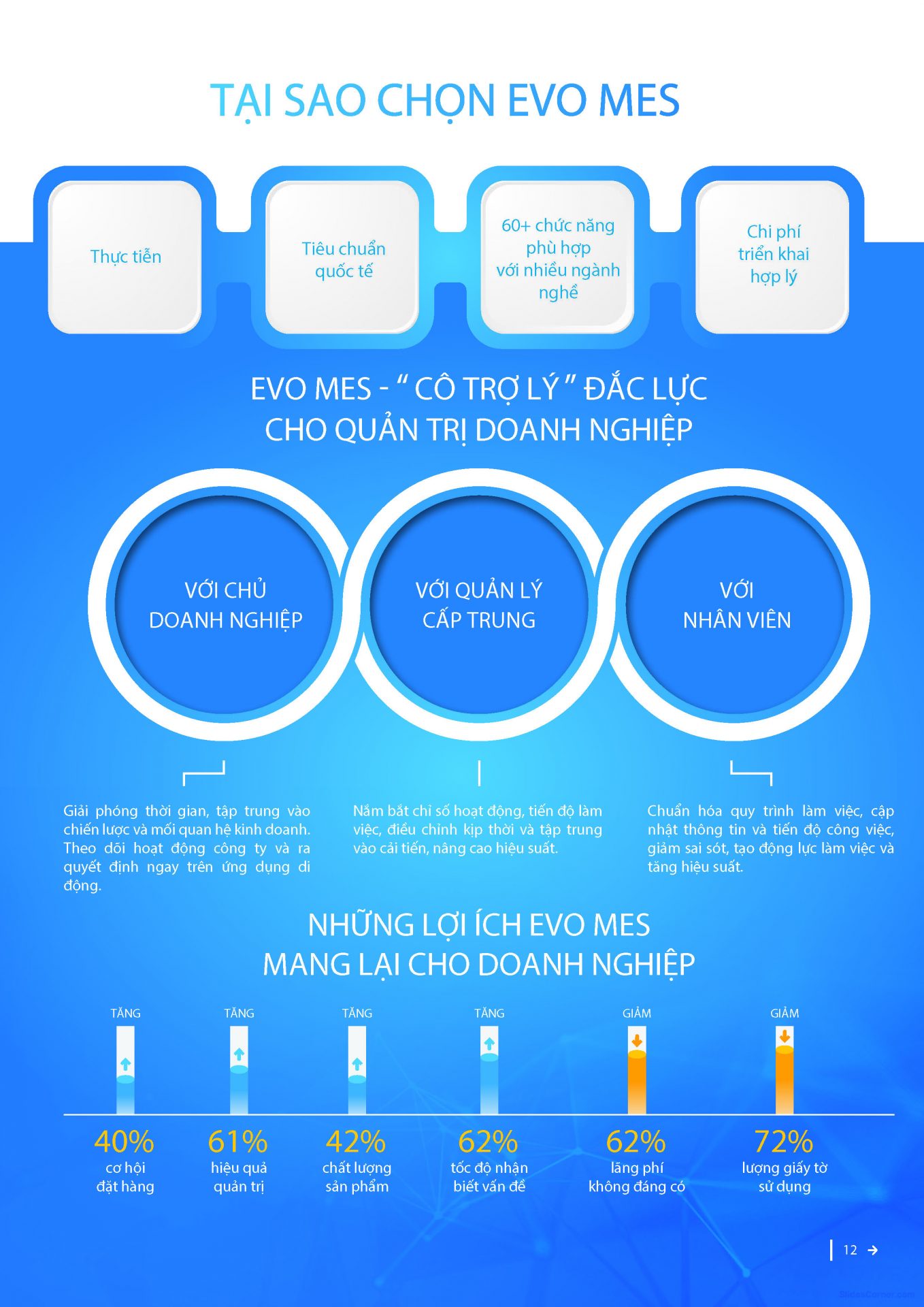

For Business Owners:

- Free up time to focus on strategy and business relationships.

- Monitor company activities and make decisions right on the mobile application.

With Middle Managers:

- Capture performance metrics.

- Make timely adjustments and focus on improvements and performance enhancement.

With staff:

- Standardize work processes, update information and work progress.

- Reduce errors, motivate work and increase performance.

3. EVO MES deployment form

- Cloud SaaS: Deployed on cloud computing platform

- On-Premise: Deployed on the customer’s information technology system

- Hybrid Cloud Use a combination of cloud and internal enterprise infrastructure.

4. EVO MES after-sales service

- Technical support: Provide technical support services via phone, email, messaging applications to support users in using the software.

- Consulting and exploitation support: Support customers to maximize the software’s features.

- Customer care: There is a dedicated and professional customer care team to listen to feedback, requests and resolve questions.

- Software upgrade: Allows customers to upgrade to a new version at a preferential cost for customers who have purchased the old version.

- Software maintenance: Provide software maintenance services periodically or upon request, including new version updates, bug patches, and system security.

5. Contact for demo EVO MES

EVOMANU Joint Stock Company

Phone number: (+84) 8.2468.9999

Website: www.evomes.vn

Address: 7th Floor, Kim Hoan Building, Lane 19 Duy Tan, Nam Tu Liem, Hanoi

[email protected]

日本語

日本語 한국어

한국어 Tiếng Việt

Tiếng Việt 简体中文

简体中文